It looks bigger and heavier than it is, but I’ve still not managed to run out of torque with it, with the normal v6 hotside or with the Supervolcano, even printing beyond what would be considered “reasonable” speeds. Speaking of the motor, the one that’s, well, not included with, but built into the Hemera is a compact-size one.

E3D also say that before running out of grip on the filament or breaking the spur gears, the motor should run out of torque and just skip a step. And I don’t even remember when exactly I last stripped filament, even with single-gear extruders. That’s on the fine side, which means there’s going to be little to no pulsation from something like a coarser spur gear chunking against the filament, but I’ve also found finer hobbing to have less of a “self-cleaning” effect, that if you ever strip your filament from a clogged hotend or messed up print settings, those shavings may not fall out on their own again, but then again, with a dual drive extruder, you’re probably never going to end up with stripped filament anyways.

I don’t know exactly which hob profile the BMG uses, but the one in the Hemera is really close to an M3 thread, but without the thread pitch. So, yeah, that’s why you do testing with your products.Īnyways, so the extruder part is basically a Bondtech BMG.

E3d hemera bowden cracked#

But this is also the pre-production Hemera unit, and this exact issue where the pinion cracked was discovered and fixed before the retail units were produced.

E3d hemera bowden full#

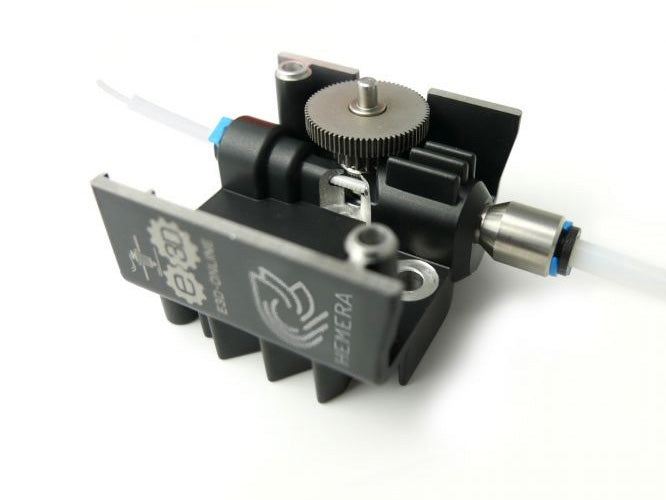

This is all pretty well miniaturized stuff, I mean that first extruder shaft is just pretty much crammed full with parts, and the reduction gears look pretty miniscule, and *gasp* is that a broken gear already? I only used this Hemera for a few kilos of PLA so far. The pinion on the motor shaft, the first extruder shaft with a larger spur gear for that three-to-one gear reduction from the motor, the hobbed section and a second spur gear to transfer the torque to the second extruder shaft, Bondtech style.īy the way, there’s a nice little IGUS bushing on the iderl. And it does eat through flexibles like a champ, there’s nowhere the filament could escape to, either because you have that Hemera-specific heatbreak go right up to the extruder gears and that’s flanked by the aluminum casing on both sides.Īnd yes, it does have extruder gears… three of them. That helps extruder precision, there’s less wiggle room for the filament to “coil up” or just compress and act as a spring, which compared to an average extruder lets you lower retractions slightly, gives more accurate extrusion, but also lowers friction, which you really need for flexibles. That makes it super compact as a unit, but also shortens the filament path between the extruder gears and the nozzle by quite a bit. The front plate of the extruder is also the heatsink for the hotend and the stepper motor’s covers do double duty as the backplate of the extruder and as mounting points. But the nice thing is, instead of having an extruder body that you use with a hotend and a stepper motor, it’s all combined into one group of parts. In fact, you can only buy it with the v6 hotside or as a Bowden version, which is just taking out the hotside and Hemera-specific heatbreak and replacing it with a Bowden adapter, aka the Bowdapter, and you obviously don’t need the fan anymore. Okay, the biggest and most obvious new thing with Hemera is that it really is intended to be used in combination with the included v6 hotside. So let’s check out what’s new and what’s different compared to what else is out there. It’s a hotend – extruder combo that I think does pretty much everything right. So this is the hot new product in 3D printing right now – it’s the E3D Herm.

0 kommentar(er)

0 kommentar(er)